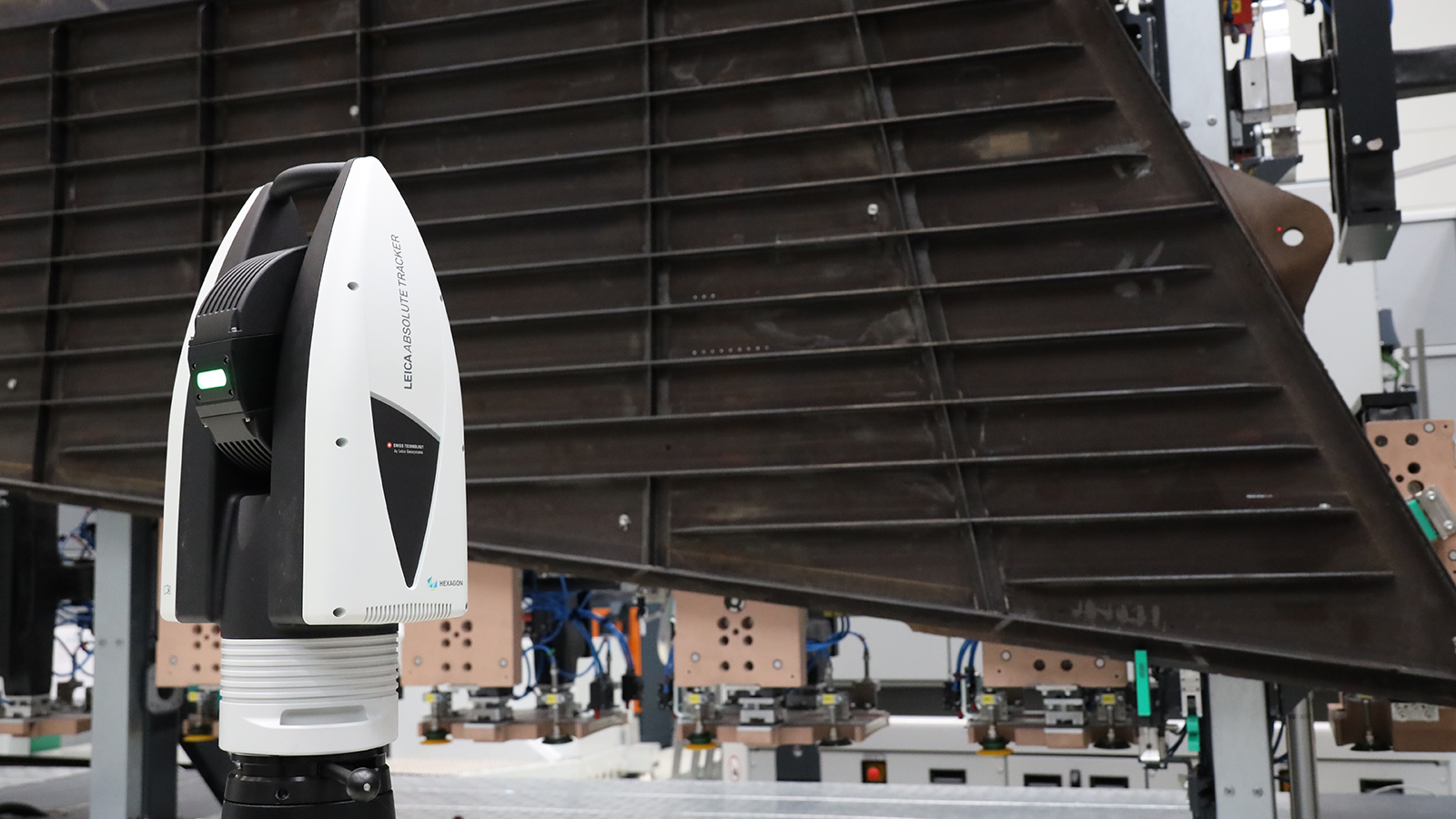

Hexagon’s new Leica Absolute Tracker ATS800 is a breakthrough in automated large-structure inspection. The ATS800 combines long-range laser scanning with real-time tracking and automation readiness – cutting inspection times from hours to minutes.

Engineered to meet the demands of faster aircraft production and labour shortages, the ATS800 enables high accuracy feature measurement from up to 40 metres away, without requiring scaffolding or physical target placement. By automating both daytime and overnight “third shift” inspections, the laser tracker frees up skilled labour for more value-added tasks and accelerates throughput.

Precision without compromise

Powered by TruePoint interferometry, the ATS800 delivers precise, traceable inspection of detailed features from up to 40 metres. With full integration of reflector tracking and real-time measurement feedback, it simplifies high-precision measurement during critical manufacturing tasks such as fuselage assembly and composite layups, and is packaged in a portable, lightweight device that can be repositioned and setup quickly.

The innovative FeatureDetect function accelerates feature recognition from CAD files or panoramic camera feeds, enabling operators to scan holes, slots and edges without manual programming or probe interaction. Compatible with commonly-used software including PC-DMIS, SpatialAnalyzer, HxGN Robotic Automation and third-party metrology and robots, the ATS800 easily fits into both existing and future automated inspection processes.

“Today’s manufacturers need faster, smarter QA processes that scale with production,” said Rodrigo Alfaia, Laser Tracker Product Director at Hexagon. “The ATS800 eliminates hours of setup and ‘boots-on-the-ground’ measurement activity without sacrificing precision, enabling digital, real-time inspection from first part to full-rate production – without compromising accuracy.”

Robotic and AMR automation

Engineered for integration with robot arms, gantries, lifts, rails, and AMRs, the ATS800 supports flexible deployment across busy production floors, and its compact form allows for flexible mounting in any orientation – even upside down. Its robust Software Development Kit (SDK) allows seamless embedding into robotic processes for lights-out inspection, dynamic position tracking, and real-time process control.

Already in use within Hexagon’s automated turnkey PRESTO Quality Stations, the ATS800 enables rapid aerostructure inspection with minimal robot motion, reducing cycle times and increasing repeatability and throughput.

Unlocking “third-shift” inspection and unattended quality assurance

With demand rising across aerospace, wind energy, and other large-structure industries, the ATS800 enables overnight, unattended inspection of multiple parts and assembled structures. Backed by PowerLock target acquisition and TruePoint scanning technology, it delivers reliable results even on steep angles or reflective surfaces, minimising the need to reposition the device and improving the measurement of challenging features.